Much more than the typical dynamometer manufacturer, MAE has slowly and steadily grown into a highly diversified, vertically integrated, technology-based engineering firm with world-class design, manufacturing, software, controls, and integration capabilities that position Mustang as a very unique supplier to the industry. In addition to a team of experienced software engineers, mechanical engineers, and electrical engineers who develop all of the company’s products and systems in-house, Mustang’s versatility and speed are its best strengths.

Quicklinks to Military Vehicle & Equipment Testing Systems:

MAE offers a wide array of services to customers all over the world. Our experienced team of engineers use the latest solid modeling CAD and CAE software and offers a comprehensive resource for your testing design and development needs. Whether your application is fully conceived or you need a design partner, the engineers at Mustang Advanced Engineering invite you to tap into their decades of experience in testing and measurement systems development.

MAE is a unique company whose expertise in the design and construction of custom test benches rivals just about any other company in the world. While custom chassis dynamometer systems have always been a large part of its core business, MAE has added a wide variety of products and has gained industry-leading expertise in nearly all types of dynamometer test benches including AC, DC, waterbrake, hydraulic, and eddy current loading units.

The current MAE product range includes engine test cells, transmission test cells, custom chassis dynamometers, production and in-process test systems, containerized test cells and complete powertrain test cells up to and including truly colossal 8×8 chassis dynamometer systems.

While some of the engineering MAE does for clients is done on a consulting basis, most of what MAE truly does best is the design and construction of custom, turn-key test systems. As a result, MAE has positioned itself as the supplier of choice when it comes to most types of custom dynamometers and test benches. MAE offers a wide range of testing and measurement solutions, custom-tailored to fit your specific testing application. MAE has systems installed in virtually every corner of the globe and provides ongoing technical support and service to an install base of tens of thousands of dynamometer systems worldwide.

Military equipment test stands include:

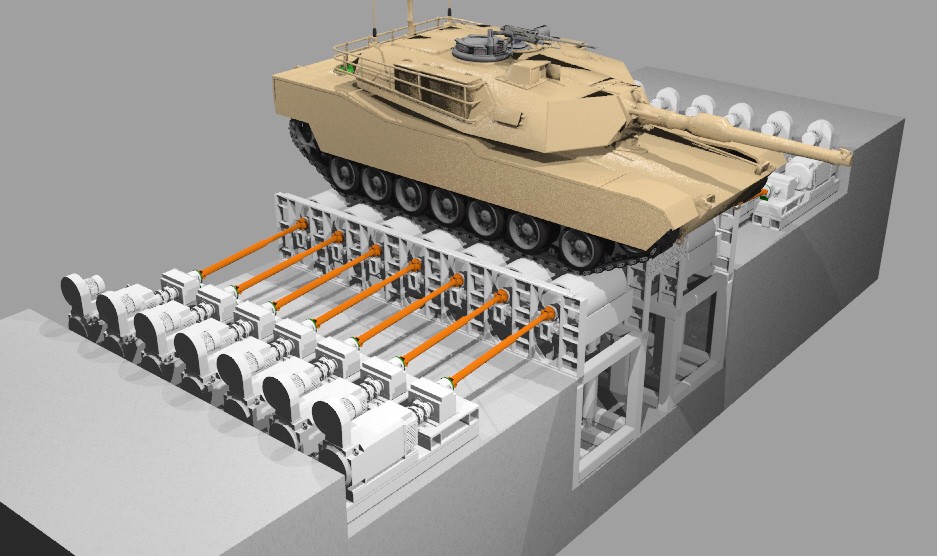

- Chassis Dynamometers

- Engine Test Stands

- Transmission Test Stands

- Aviation Test Stands

- Generator Test Stands

- Final Drive Test Stands

- Angle Drive Test Stands

- PTO Test Stands

- HSU Test Stands

- Ballscrew Actuator Test Stands

Mustang can supply component level production test stations and total vehicle test stations. Typically, Mustang is performing audio, chemical, electrical, electromagnetic, physical and visual testing in our processes. Sample Of General Testing:

| Speed Validation | Torque Validation | Mechanical, Thermal & Electrical Power Validation | Force Validation |

| Flow Validation | Pressure Validation | Sound Validation | Vibration Validation |

| Temperature Validation | Displacement Validation | Placement Validation | Dimensional Validation |

| Surface Validation | Visual Validation | DVM Electrical Measurements | Particle Validation |

| Compound/Chemical Type & Quantity Measurement | RFI/EMC Electrical And Electromagnetic Validation | Thermal Imaging |

Vehicle Testing:

The total vehicle test station usually deals with wheeled or track vehicle testing which typically requires a test cell to be established with a pit, supply air and exhaust. The testing equipment is based on the required testing specifications for the vehicle. This can be a simple speed and load test or a compressive series of test to fully test and shake out a vehicle to verify production quality. Depending on the vehicle and it’s testing requirements Mustang can design the appropriate equipment to test the vehicle to validate the production of vehicle. During these tests many vehicle and test stand parameters are measured, monitored and compared to verify proper operation of the vehicle while under test. Sample Of Vehicle Testing:

| Engine Power Testelectric Motor Power Test | Engine Speed Testelectric Motor Speed Test | Vehicle Speed Testing Fwd/Rev | Wheel Force/Hill Climb |

| Parking Brake | Foundation Braking | Exhaust Brakes | Electric Motor Braking |

| Wheel Speed Sensor Validation | Abs Braking System Validation | Vehicle Engine Monitoring Over Communication Bus | Vehicle Simulation Long Distance Testing |

| Transmission Shift Points | Head Light Alignment | Wheel Alignment | Shaker/Shock Testing |

| Acoustic Sound Measurement | Lift Loading Simulation | Vibration Measurement And Monitoring | Visual Inspection Camera, Video, Thermo-Imaging |

| Exhaust Emission Measurements | Emc/Rfi Measurements | Exhaust Flow, Temp, | Blow-By Measurements |

Component Testing:

Many different components and sub components require assembly and test prior to being installed into a vehicle. Mustang can design the appropriate equipment to assist in the assembly of the component(s) and perform the required testing and validation. In many instances visual or gauge testing is used for process validation. Sample Of Component Testing:

| Engine | Transmission | Hydrostatic Unit (HSU) | Transfer Case |

| Axle | Wheel End Gearbox | Angle Drive Gearbox | Drive Shafts |

| Electric Motor | Alternators / Generators | Starter | PTO |

| Compressor | Pump | Interface Assembly (IA) | Solenoid Tester |

| Valve Body Tester | Cab Tester, Turret Tester | MIL-1553 Bus Simulator |

Helicopter, Tilt Wing & Aircraft Component Applications

| Main Transmissions | Tail Rotor Gearbox | Intermediate Gearbox | Combining Gearboxes |

| Nose/Input Gearbox | Turbine Engine | Accessory Gearbox | Cab Testing |

| Rotor Head Testing | Tail Rotor Testing | Blade Testing | Starter |

| Alternator/Generator | APU | Wheel Braking Systems |

Other Component Applications

| MIL-1553 & MIL-1773 Bus Component Simulation Sys | Track Wheel Denuding System | Armor Moving Target Carrier (AMTC) | Landing Gear Inertia Systems |

| Sight Alignment Systems | Torpedo Test Systems | Ball Screw Actuator | Inertia Test Stands |

| Rate Of Fire Counter |

Software:

Mustang can assist with process software to monitor and validate production building of a component or vehicle.

MD Production Process Software:Mustang offers a single or multi-station production processing software system which allows manufacturing or remanufacturing facilities to document and monitor the manufacturing process. The configurable software is arranged in a station by station configuration. A station by station process flow chart is developed and the software is configured to follow the process flow and is easily expandable based on test article’s incoming part number. The Production Process software monitors the operators, Incoming component tracking, inventory level and notices, station assembly instructions, video station training, testing pass/fail criteria, report generation, equipment calibration tracking, process flow charts, statistical information, retest. The software configuration starts with the finished product and works backwards to each station involved with the manufacturing or remanufacturing of product including teardown.

Military Equipment Update, Upgrade, Retrofit, Repurposed, Refurbish & Relocate Service

Mustang can assist you with the Update, Upgrade, Retrofit, Repurpose, Refurbish and Relocate of your current equipment. We can assist with relocating your equipment adding updated software and controls to your existing equipment. We can perform these duties on site or we can perform these tasks in our facility. Mustang has worked in many different and difficult environments to service our customer and their equipment.

At MAE we listen to our customers’ requirements and needs then we develop an Expectation Plan and review it in detail with our customer to verify we meet all of their needs. The Expectation Plan will be different depending on the project, the Expectation Plan typically consist of:

- Project Overview

- Reuse of Existing Equipment

- Added New Equipment

- Scope of Work

- Project Specifications

- Resource Requirements

- Time Line

- Pricing

Military items that MAE can Update, Upgrade, Retrofit, Repurposed, Refurbish and/or Relocate:

- Software, Control, Data Acquisition Systems

- Helicopter and Tilt Rotor Component Test Stands

- Transmission Test Stands and Components

- Transfer Case Test Stands and Components

- Engine Test Stands and Components

- Turboshaft, Turbojet, Turbofan, Turboprop Test Stands and Components

- Electric Motor & Hybrid Testing Systems and Components

- Axle Test Stands and Components

- Gearbox Test Stands and Components

- Wheel End Assembly Test Stands and Components

- Tire and Wheel Test Stands and Components

- Driveline, CV-joint, U-Joint, Test Stands

- Landing Gear, Brake and Inertia Test Stands

- Generator, Alternator & Starter Test Stands

- Chassis Dynamometers and Components

- Power Absorbers: Eddy Currents, Water Brakes, Hydraulic Brakes, Hysteresis Brakes,

- Motors, Generators, Gearboxes, Transmissions, Pumps,

- Machine: Shafting, Bearings, Gearing, Splines, Keys, Couplings, Clutches, Torque Limiters,

- Hydraulic Loading Systems, Hydraulic Power Supplies (HPU), Cylinders, Valves, Hoses

- Gas Analyzers and Support Components

- Water Towers and Cooling System

- Exhaust Extraction Systems

- Throttle and Brake Actuators and Fixtures

- HVAC systems for test cell and facilities

- Fans and Blower

- Sight Alignment Systems

- Torpedo Test Stands

- Whirl Towers and Blade Testing Systems

- Wind Turbines and Components

- Tow Dynamometer and Components

- Flywheel and Inertia Systems

- Wind Tunnels and Components

- RFI &EMC Chambers and Components

- Anechoic Chambers and Components

- Environmental Testing Chambers and Components

- Facility Infrastructure and Safety Systems

- Electrical Distribution System, Motor Control Centers (MCC), Transformers,

- Battery Simulators, Battery Loading Units,

- Motor Drives, Regenerative Motor Drive, Common DC Bus Motor Drives, Dynamic Braking Resistors,

- Cable, Conduit, Pipe, Tube, Hose and Duct Management Systems for the Facility and Equipment

Specialty Military Test Systems

Mustang is an engineering and manufacturing company immersed in the forefront of technology. We are routinely contracted to support our customers manufacturing and testing requirements by supplying our vast engineering expertise and our customers product knowledge to design a product to meet our customers needs and expectations. Many of these products that we engineer and produce are the first of their king and have special uses.

Examples of Military Specialty Test Systems of these items:

- Torpedo Test Stand

- Sight Alignment & Calibration System for Targeting Systems

- Rate of Fire Counting System

- MIL-STD 1553 Bus Component Simulation

- Road Wheel Denuding Machine

- Vehicle Ball Screw Actuator Test Stand

- Flywheel Inertia System

- Specialized Test Cell Software Upgrade

- Ruggedized Infield Computer and Control Systems

- Landing Gear Test Stand