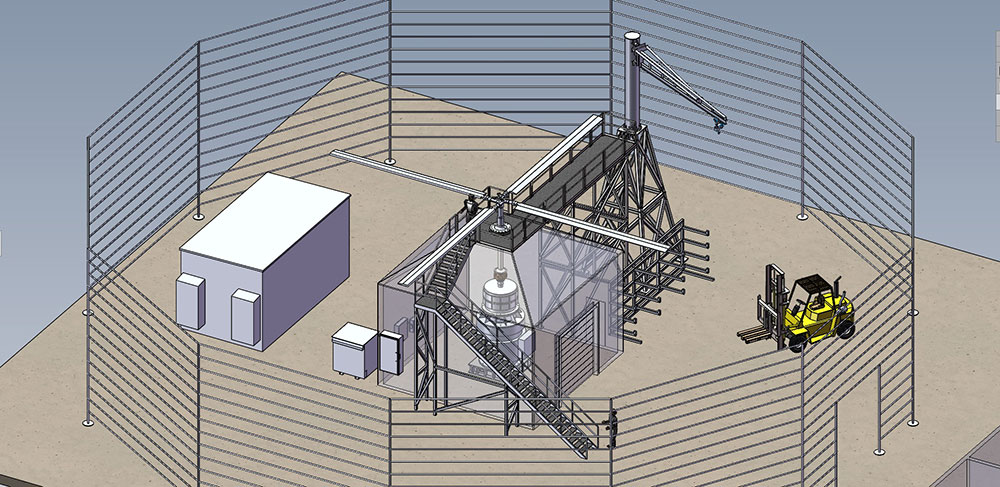

Whirl Towers

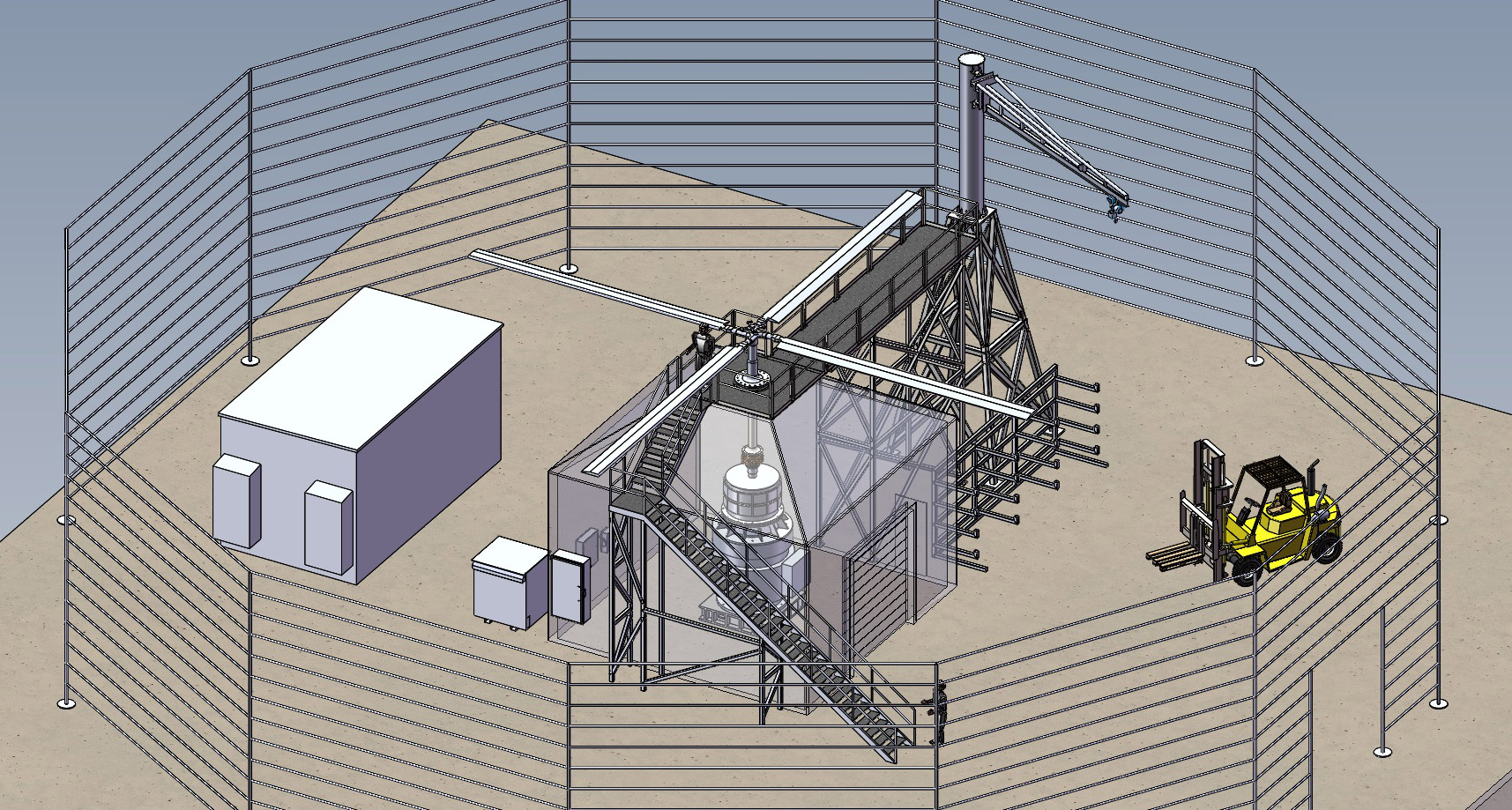

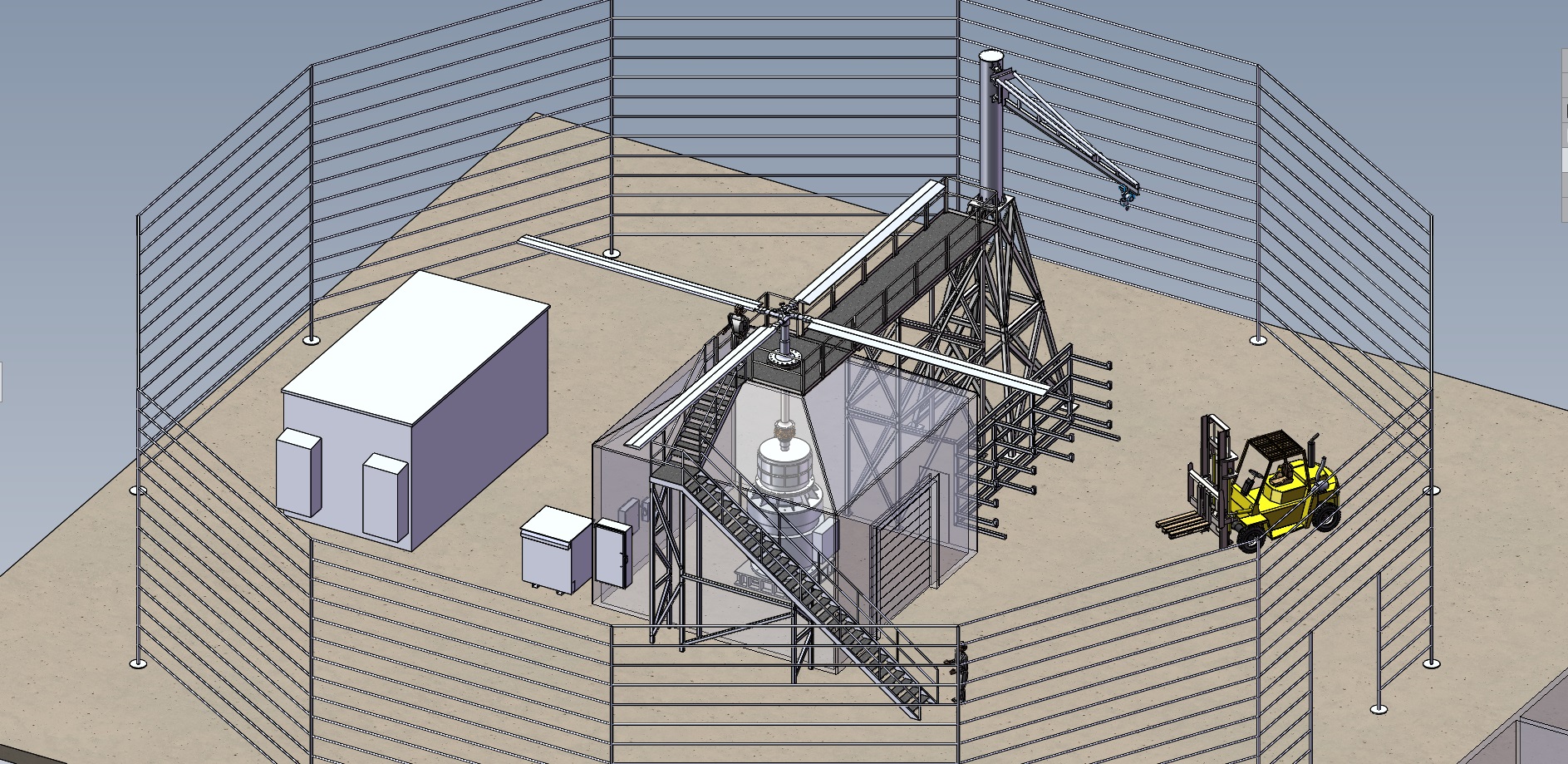

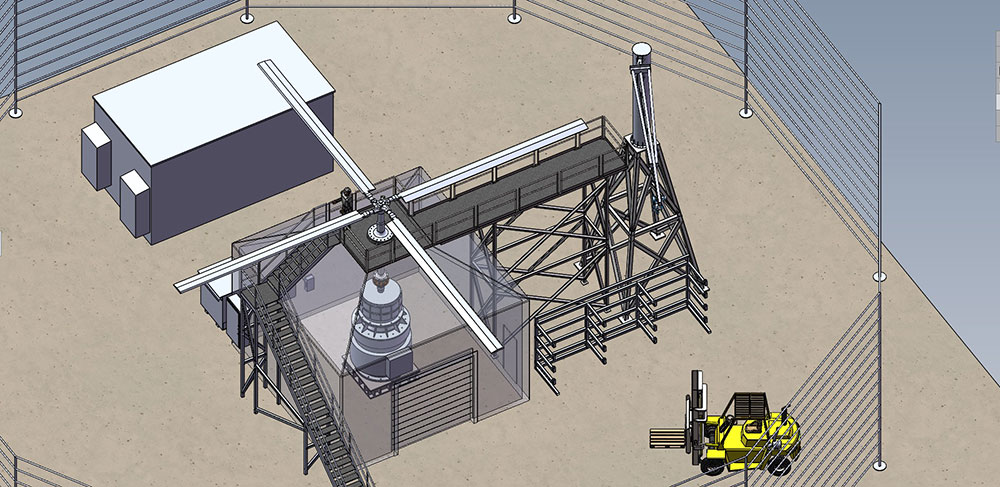

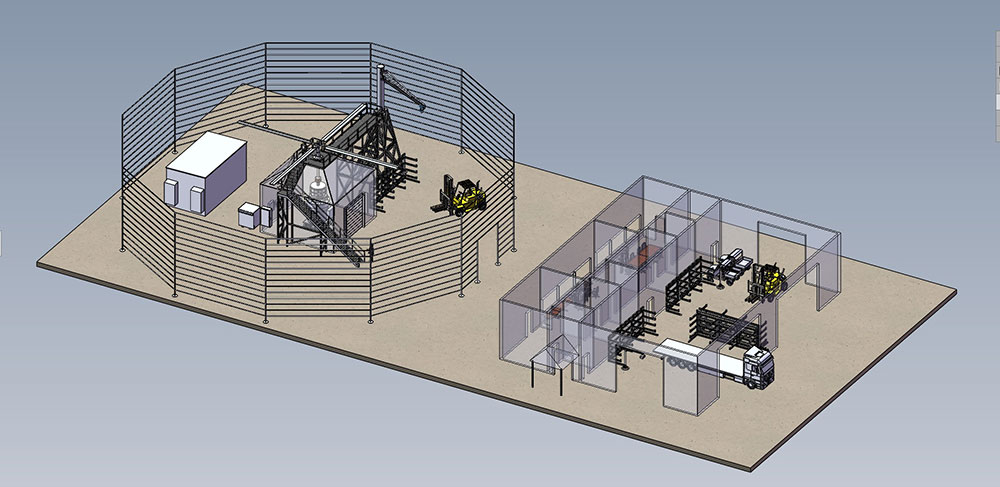

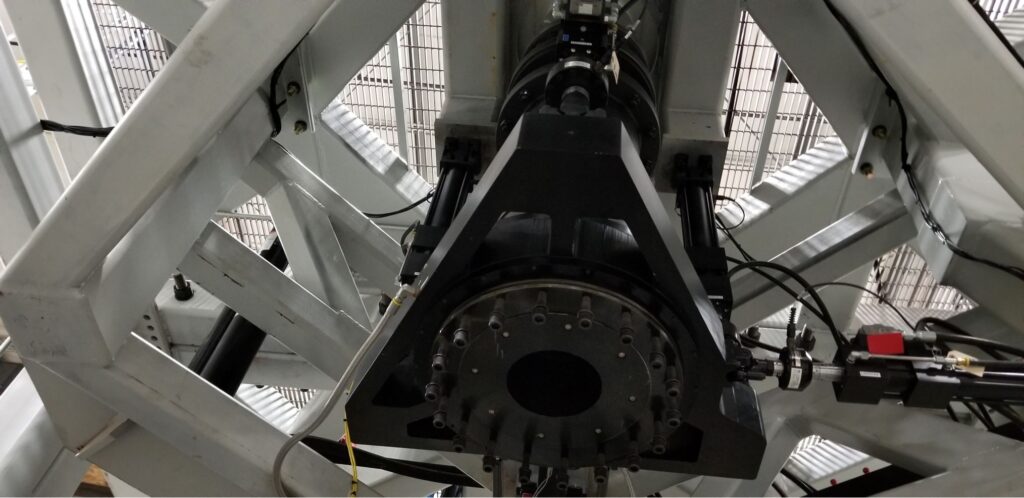

Whirl Towers are used in rotorcraft blade balancing, blade development, main rotor hub system development and performance analysis such as blade lift/thrust or blade hover envelope during varying or constant blade speeds. The Whirl Tower can be simple or complex system, small or large depending on the customer requirements. Blade systems can be developed for large manned and smaller unmanned (Drone) system.

Small systems can operate blades at thousands of rpms while large systems typically operate under 250rpm. Current and future research and development on blades and propellers keep researches constantly evaluating materials, active blade structural and to reduce ice formation, sound, balance and vibration. Through the use of these Whirl Towers increase blade and main rotor hub systems efficiencies are determined smaller diameter, high power and higher speeds blade systems are being developed and require validation and testing. Counter rotating Co-Axial rotor testing system can be supplied for testing blades and full head development.

Whirl Tower Systems can vary in size from small single digit Hp (kW) to large thousands of Hp (kW). MAE can supply your next Whirl Tower System. MAE has the engineering, manufacturing, construction and field support capabilities to be your supplier. We can repurpose, up-grade an existing facility or start from scratch.

Whirl Tower Features:

- Bi-directional Operation

- Scalable Power Capabilities up to 25,000Hp (18,750kW)

- Unique Rotor Head Design and Mounting for Reduce Structural Vibration

- Ultrahigh Accuracy Rotor Head and Pitch Control Sensors with Telemetry system

- Remote Mounted Laser Blade Measuring System with Pulse Marked High Speed Camera available.

- Designed with Weather Resistance Material and Enclosures for Temperature Control as required.

- Vestal and Fast Blade Lift System for Quick Blade Interchange.

MAE supplies Test Stands, Software & Controls, Test Cell Support Equipment, Engineering Services, Installation Services and Refurbish Services to many portions of the Military and Aerospace Industry. Our commitment, applied ingenuity, supply of equipment & services to these Industries, has made MAE a premier supplier to these Industries.

MAE has supplied many integrated Standard and Engineered Test Stands to the Military and Aerospace Industry. We have also supported the Industry with Test Article Support Equipment, Test Cell Support Equipment, Software, Control and Data Acquisition Systems, Facility Support Equipment, Installation & Training Support as well as Turnkey Systems. MAE has work with many Customers as the prime contractor, subcontractor and simple component supplier.

MAE is a 35 plus year old vertically integrated United States of America manufacturing and engineering company with turnkey capabilities. We use a proven and logical approach to develop and manufacturing equipment to meet our Customers’ requirements and needs. Over the past 35 years we have developed many testing and software solutions to draw experience from in developing new solutions to our Customer’s specifications and needs. Some of these solutions are modified existing projects or totally new concepts solutions whereby MAE uses in-house expertise and out-of-house expertise coupled with the Customers knowledge and needs to develop a solution.

MAE Competencies

- Engineering

- Project Management

- Mechanical

- Electrical

- Software

- Control

- Hydraulics

- Architecture

- Manufacturing

- Material Handling & Storage

- Material Processing

- Material Fabrication

- Material Paint Shop

- System Assembly with 30-Ton Overhead Crane System

- Panel Build Shop (UL508 Listed)

- Cable & Wire Harness

- VFD Cabinet Assembly Area

- Quality

- ISO 9001:2008 Certified and Registered

- Calibration Certification Capability

- Quality Lab and Equipment Area

- Test and Verification

- Dedicated Mechanical Test Out Area

- Mechanical Assembly Tools, Gauges, Alignment Tools, Vibration & Sound Measurement equipment,

- Electrical Lab support up to 2MWatts to Mechanical Test Out Area

- Electrical Assembly and Monitoring Tools, Gauges, Meters, Meggers, Loggers,

- Hydraulics Assembly Tools, Various Gauges, Various Sensors temperature, pressure & flow sensors, filters

- Training

- In-House Training

- Out-of-House Training

- Operation

- Maintenance

- Calibration

- Documentation

- Commissioning

- All support levels up to Turn-Key

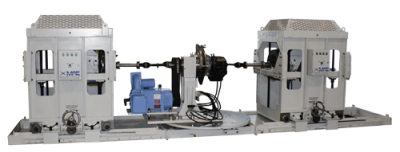

helicopter transmission Testing

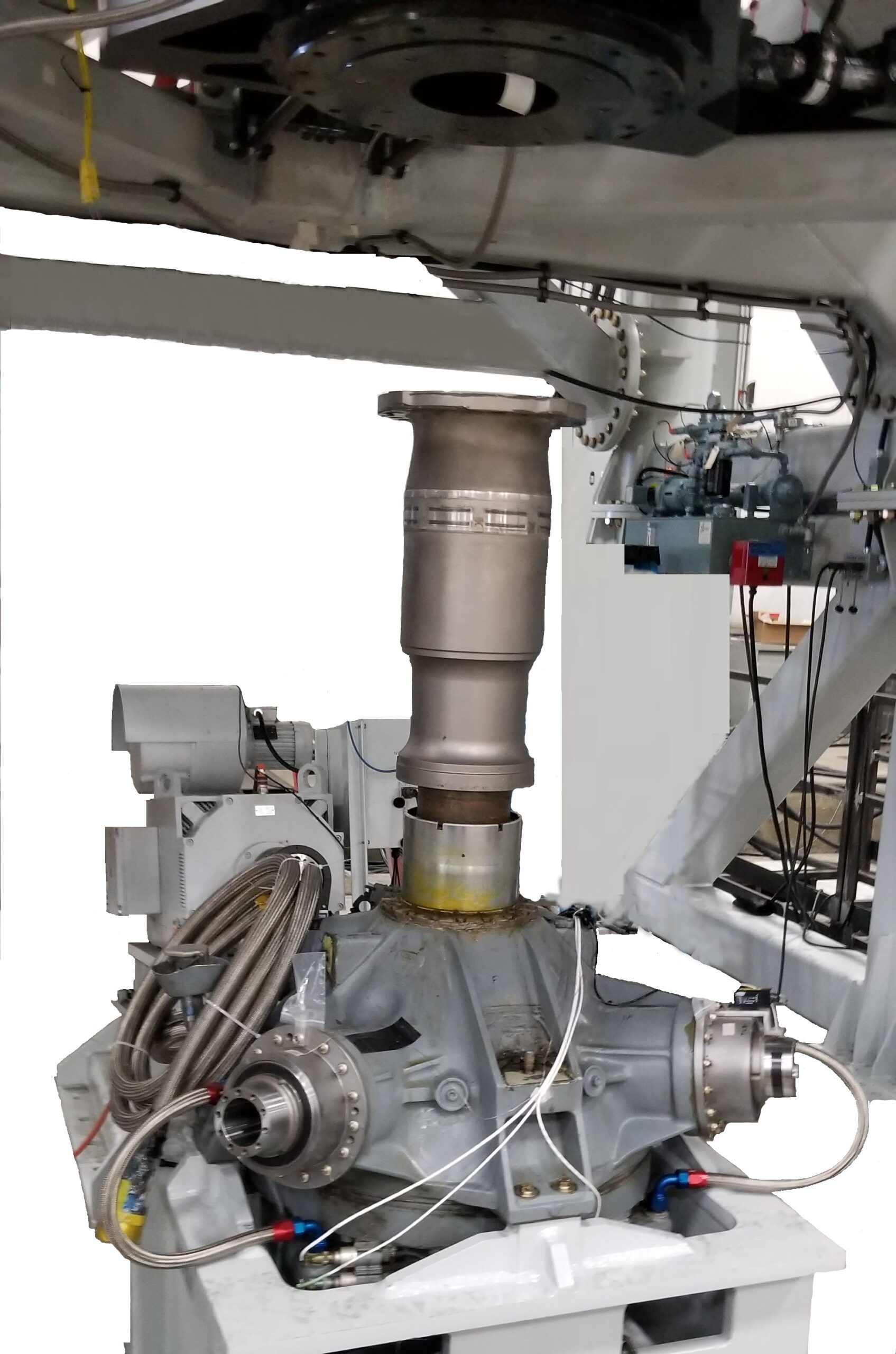

The helicopter transmission, just as well as engines and rotors, require highly sophisticated and technically advanced transmission test systems to develop a technology base for future rotorcraft advances.

Standard Features

- Direct-connected AC Variable Speed Input Dyne Motors

- Directly connection OR 90° gearbox connection available for main mast AC output motor

- Highly responsive inertia simulation capability

- Accurate and responsive speed synchronization

- Regenerative variable speed AC dyne systems

- Modify speed and torque based on transmission config.

- No water required to cool system

- Highly-efficeint power utilization reduces energy costs

- Optional Force Blade Simulation Systems available

Helicopter, Tiltrotor and Rotorcraft aircrafts require testing of their individual powertrain components as well as the completely assembled powertrain system. MAE specialized in testing these individual components and fully assembled powertrain systems. Testing can be a simple spin-up loaded test or complex inflight simulation testing using 6-dof hydraulic blading loading simulators attached to Mast/Tail rotor/Tiltrotor blade shafts. MAE is capable of meeting your testing requirements and needs.

MAE supplies a larger variation of test stands for the aviation industry, some test stands are airframe specific, other test systems work across a various airframe sizes and configurations, while other test stands are product specific or operate across various product sizes. MAE will meet your testing needs for Production, R&D and Remanufacturing Validation Test Stands.

Samples of Test Stand Types: Some of these Test Stands can be combined for partial powertrain testing

- Main Transmission

- Tail Rotor & Intermediate Gearbox

- Combining Gearbox

- Nose/Input/Engine Gearbox

- Accessories Gearbox

- Complete Aircraft Powertrain

Not all of our aircraft systems are big, MAE supports and supplies smaller test stands to support accessory drives, APUs, generators and gearboxes. We will work with you to develop a cost-effective testing solution.

Test Stand Features

- High Power +40,000Hp (35MW) capabilities

- High Speeds upto 80,000rpm

- High Torque + 1,300,000 Lb-ft (1,780,000N-m)

- High Structural Integrity of Test Stands using FEA modeling.

- Various Variable Speed AC motors Configurations

- Various Digital Variable Frequency Motor Drive Configurations

- Various “4-Square” Mechanical Recirculation Powertrain Loading Configurations

- Available with Mast, Tail Rotor shaft or Tiltrotor shaft Hydraulic Loading Units.

- Test Article Cart Loading Systems

- High Precision Torque and Speed Measuring systems, Contact and Noncontact Versions

- Torque Limiters are available on shafting

- Software & Controls for Inflight Simulation using 1 to 6 DOF Loading Unit and Input/Output Loading.

- Software for Dedicated Customer and/or NMWR/DMWR testing procedures.

- Optional Force Blade Simulation Systems available

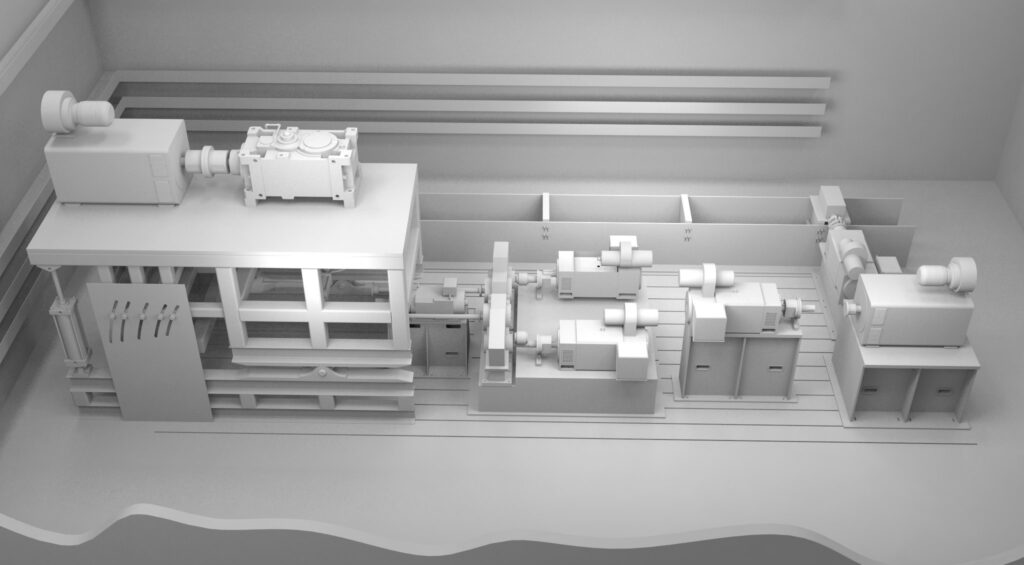

The helicopter has evolved into a highly valuable air mobile vehicle for both military and civilian needs. The helicopter transmission, just as well as engines and rotors, require highly sophisticated and technically advanced transmission test systems to develop a technology base for future rotorcraft advances.

Research studies continuously aim to increase the life, reliability, and maintainability, reduce ther weight, noise, and vibration, and maintain the relatively high mechanical efficlency of the gear train In helicopter transmissions while also identify advanced materials and lubrlcation schemes, as well as advanced design concepts for both transmission components and total transmission systems.

Mustang Advanced Engineering is one of only a few companies in the world that has developed systems and possesses the experience to deliver the the highly specialized testing solutions demanded for this application. MAE has experience building advanced testing solutions for helicopters like the OH-58 Kiowa and the AH-1, the Kawasaki OH-1, the Bell 47, and the HH-60G Pave Hawk. The experienced team at MAE are experts at creating custom solutions to fit specific testing

Transmission and high-speed gearbox testing applications have long been a specialty and area of technical expertise for the team of testing and applications engineers of Mustang Advanced Engineering. Regardless of the unique challenges of your application, MAE has an complete systems solution to meet your helicopter transmission testing needs.

MAE is widely regarded as a leading global provider of dynamometer systems for a wide range of applications that require accurate and repeatable inertia simulation, speed control, force control or acceleration control. Mustang’s line-up of dynamometer and test systems have evolved and acquired techniques and capabilities resulting from decades of experience in developing “high accuracy” simulation and test systems.

- Direct-connected AC Variable Speed Input Dyne Motors

- Directly connection OR 90° gearbox connection available for main mast AC output motor

- Highly responsive inertia simulation capability

- Accurate and responsive speed synchronization

- Regenerative variable speed AC dyne systems

- Modify speed and torque based on different transmissions

- No water required to cool system

- Highly-efficeint power utilization reduces energy costs

- Optional Force Blade Simulation Systems available