MAE has a vast software library operating many different Testing, Production and Monitoring Applications. Mustang Advanced Engineering’s software group is able to configure or develop a software application for your requirements.

Standard Features

- Mobile/Portable Test and Data Acquisition Systems

- Test stand software

- Test Cell Control and Data Acquisition Test System software

- Test Facility System (enterprise solution that allows for secured remote web access to Test Cell Data)

- Robust Production Testing Software

- Inspection/Maintenance Testing Lanes software

- Vehicle Tuning, Repair and Diagnostic Systems software

Mustangs supports many software platforms and custom testing software. Some of our standard software packages are listed below:

- TESTCell Software Suit: is able to handle most test cell, production stand, and standalone applications.

- PowerDyne Software Suit: is primarily developed for Chassis Dynamometer Applications with Emission Analyzers, Battery Simulation, Robotic Drivers, Vehicle Cooling Fans, Facility Management Systems, Large Scale Data Acquisition System, PLC Controllers, Embedded Controllers, 3rd Party Controllers, Custom Controllers and more.

- ProductionPro Software Suit: is primarily developed for Production Process Flow Applications into existing production process environments

- Tow Dynamometer Software: This product is used with our pull only and our push/pull style tow dynamometers and ancillary interfaces

Mustang also supports many other test equipment specific application needs with custom software.

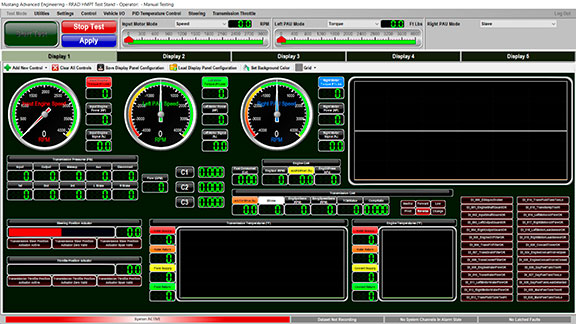

TESTCell

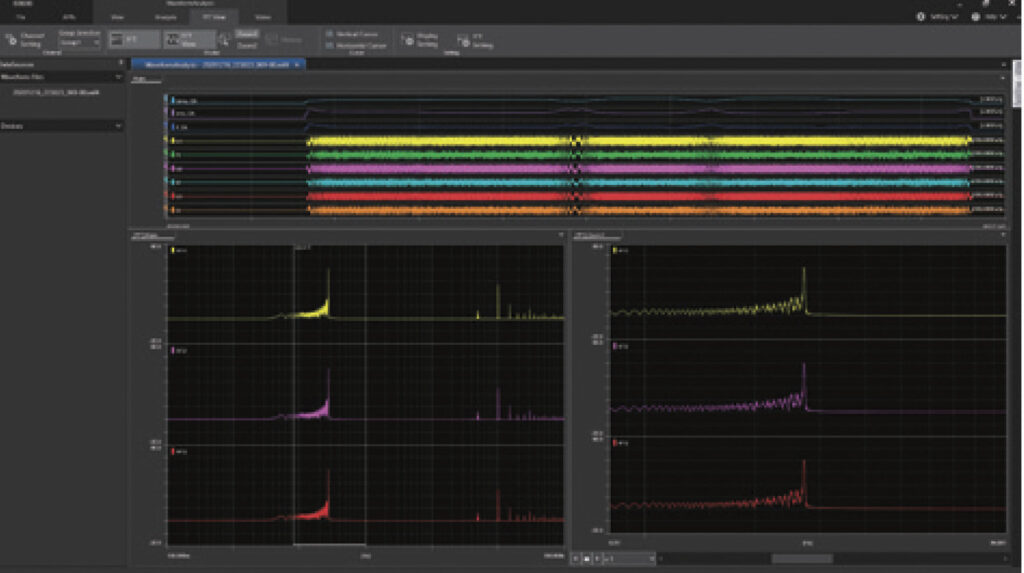

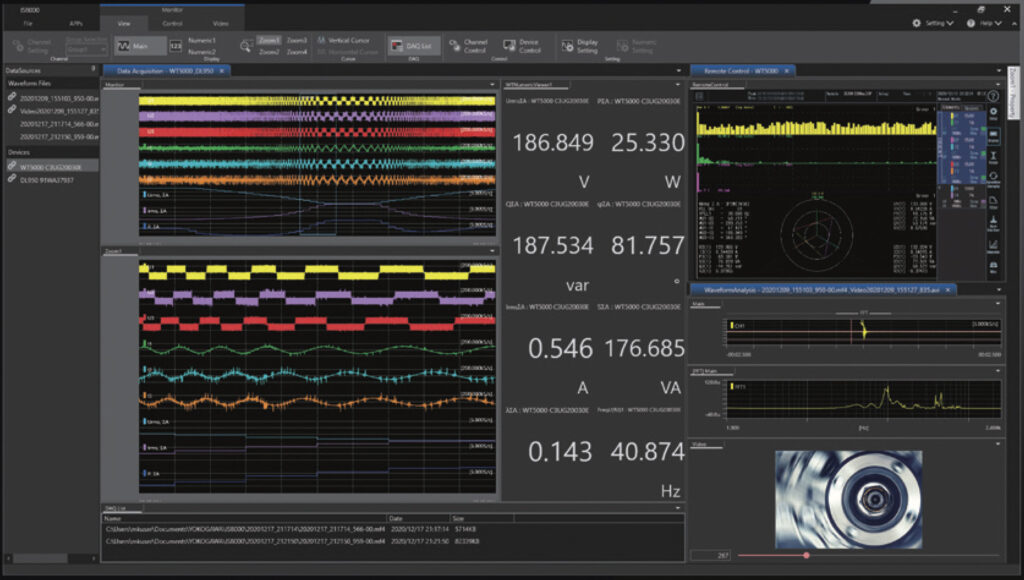

MAE’s TESTCell Software Suit is able to handle simple to complex test stand control test sequences, data acquisition, data displays, database storage, reports and more. The TESTCell Software is a configurable software package allowing Mustang to use proven pre-existing low level software blocks while developing application specific displays, testing requirements and test stand control. This flexible software allows the operator to develop there own screens, calculated data channels, modify reports, adjust for for user security levels. The software is idea for laboratory and production applications.

Features:

- Enhanced Color Graphics Operator Display Interface

- Real-Time Configurable Display Screens with Storage and Instant Recall Tab Selection

- Multiple Language Support and Configuration

- Testing Modes: Scripted Test, Automated, Ramp & Set-point, Custom Test

- Script Testing Modified by the Customer, Saved, Recalled, Copied, Pass/Fail Levels, Step Test Conditional Statements to Step, Report Generation Based on Pass/Fail

- System & Operator Security with Operator Database and Access Level Selection

- Dynamometer Configuration and Parameters Supporting PAU Type, PID Loops, Maintenance Screen, System Shutdown values

- System Channel Editor; Configuration New Channels with Channel Editor developing algebraic equations as channels using existing channels, algebraic expressions, constants, variables, powers and other expressions to develop new system data channels.

- Channel Properties allows the operator to calibrate the system channels, Develop Warning levels, Shut Down levels, assign display colors based on levels, the number of digits after the decimal point can be assigned, channel names, engineering units changing based on individual channel value

- Data Acquisition Properties; The Data Channel List is selected with individual channel having separate data acquisition sampling rate assigned, the Data Set Output File and Destination can be selected, the Data Channel has several version such as raw, filtered, min, max, average these individual channels can be selected to be displayed and recorded.

- Data Set Sample Channel List: Development, Save Location, Recall, Search Parameters

- The Data Set can be filtered for recall by Date, Operator ID, Test ID, Part Serial #, Part #, etc.

- Testing Report Generation, pass/fail parameters are established during test development then the report can be recall and printed.

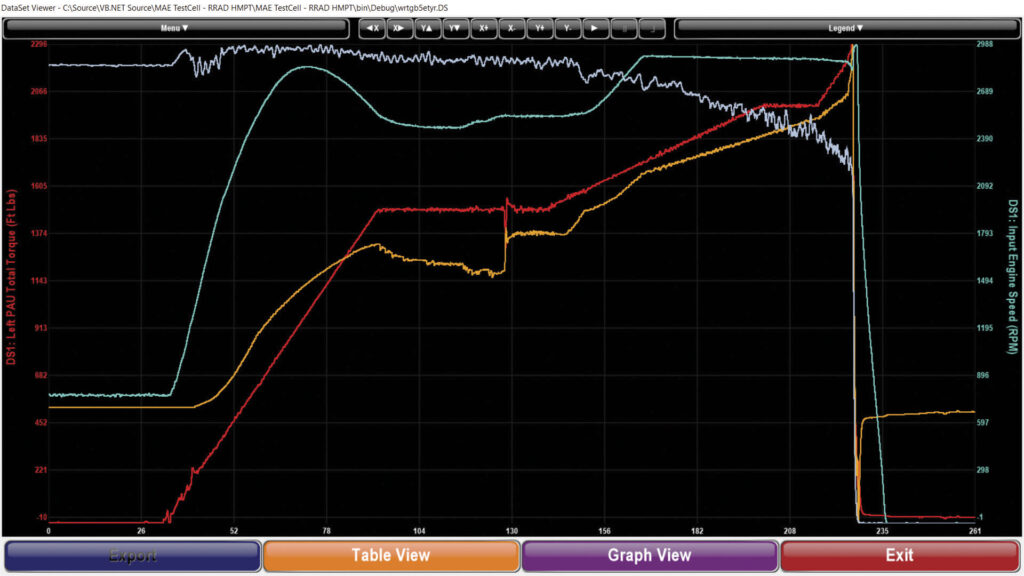

- Data Set /Graph Viewer; Data can be retrieved, viewed and analyzed on an enhanced graph viewer with zoom and filtering capabilities. Data can also be reviewed in a tabular format, Data can be exported and printed.

Other Software Available:

Hole Shot

The modern world is changing faster than ever before and most companies and governments are migrating away from older Windows based networking technologies to web-based networks that are endlessly interconnected making information easier to share and easier to access from any device at any time. Mustang adopted web-based technology in 2016 when it embarked on a new project to advance dynamometer technology and simplify its offerings. Mustang’s goal was to increase commonality and provide customers with a more powerful and easier to manage controls package. Mustang already offered a full menu of testing capabilities, so we turned our attention to increasing access and decreasing clutter. By adopting web-based systems, Mustang can better service thousands of customers world-wide from one location and keep all of our customers on the most up to date system available. All enhancements can be pushed to all of our customers at the same time making sure all installations are up to date. Our latest controls package is designed to keep our customers constantly ahead of the curve and ensure that their valuable data is secure and backed up to a secured cloud database.

The Hole Shot server processes data using the DAC32’s 32-bit, 80 MHz microcontroller with 512 kb of FLASH program memory and its 128 kb of static RAM. The system is capable of greater than 1 kHz loop controls and communications. The controller has 16 digital inputs, 16 digital outputs, 16 analog inputs, 8 analog outputs, 4 frequency inputs and high speed ethernet based communications. The DAC32 is responsible for all dynamometer control and data collection while leaving vehicle data collection to optional USB, Bluetooth or wi-fi based modules. The server connects to the dynamometer’s torque and speed sensors as well as the lift control solenoids via a multi-pin harness. The eddy current brake(s) is controlled via an AC/DC controller mounted in a sturdy wall mounted NEMA cabinet.

To Find out more about Hole Shot software, Click here for information from Mustang Dynamometer!