Mustang Advanced Engineering offers a variety of test fixtures, Test Stands, hardware and components, such as:

Engine Docking Carts

Charge Air Intercoolers

Engine Cooling Modules

Fuel Measurement and Conditioning Modules

Transmission Control Module

Throttle Control and Pedal Actuators

Engine Docking Carts

Mustang’s heavy-duty engine docking carts include heavy-duty casters and engine mounting and leveling hardware to make setting up engines more efficient.

Standard Features

- Heavy-duty 8″ casters, Two (2) rigid and Two (2) swivel casters.

- Cart reciever with dual clamping locking device.

- Heavy duty jackstands (2)

- Universal Mounting Flange

- Vibration mounts for jackstands mount to the end of the jackstand and adapt the jackstand to the engine rear support mounts

Mustang’s Engine Docking Carts allow you to set-up engines for testing quickly and easily. When one engine is finished testing, roll the next one up to the dyno, lock in down, attach the drive shaft, hook up your sensor and start testing.

Mustang offers a number of Engine Docking Carts to make mounting and setting up engines for testing a snap. Our docking carts include all of the hardware and components you’ll need to securely mount and level engines and prep them for dyno testing.

Mustang’s standard cart is a heavy-duty, welded and finish machined 3″ dual channel section frame with removable handle, and a 12-ga. drip pan. Two 1-1/2″ wide tee slots on 24.5″ centers are provided the full length of each side to provide adaptability to a wide variety of engine sizes. Two rigid and two swivwl 8” casters are proven to handle 1,200 lbs. Included with the standard cart package is one complete cart, cart receiver, engine jack stands and vibration mounts.

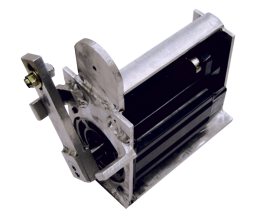

Charge Air Intercoolers

Maintain engine air temperature to intake manifold at a user-defined temperature.

Standard Features

- Maintain engine air temperature to intake manifold at a user-defined temperature.

- Less than 2 PSI pressure drop across the cooler system.

- Both manual override and electronic controls to the system controller.

- Hot air is cooled to within 50°F of facility water.

- Uses less than 20 GPM facility water.

In operation, 350° F turbocharger compressor discharge air is routed through large diameter primary pipes to a new, low restriction, high-efficiency air/water heat exchanger core. The hot air is cooled within 50°F of the facility water. In other words, it the facility water temperature is 90° F, the 350°F air is returned to the engine at 140°. This is a 210°F reduction in air temperature. Exhaust temperatures are reduced an equal amount. The cooled air is returned to the engine through large diameter secondary pipes. The system’s pressure drop is less than 2 PSI due to large primary and secondary pipes, as well as an extremely low restriction heat exchanger.

The temperature control system utilizes a dedicated temperature controller, which is programmable either by its panel buttons or via a serial link to the control software system. The controller also reports the air temperature back to the control system via the serial link. The temperature controller regulates the cooling water through the heat exchanger as required to cool 1,000 SCFM of up to 350°F air to 140°F with only 2 PSI drop using less than 20 GPM facility water.

Engine Cooling Modules

Mustang’s Engine Cooling Module is a portable shell and tube heat exchanger that is designed to replace the engine radiator and maintain a constant engine temperature.

Standard Features

- Eliminates the need for radiator, fans and belts for added safety and convenience.

- Ensures maximum cooling

- Cost effective design

Mustang’s Engine Cooling Module is a portable shell and tube heat exchanger that is designed to replace the engine radiator and maintain a constant engine temperature while an engine is being run on a test stand and under dynamometer loading.

Mustang’s Engine Coolant Cooling System uses industrial high pressure water to glycol/water shell and tube heat exchanger systems. The heat exchanger is fitted with pressure gauges, temperature gauges, control valves, and relief valves in a convenient portable package with wheels and a handle.

Fuel Measurement And Conditioning Modules

Mustang’s Fuel Measurement and Conditioning Module utilizes a Coriolis mass flow meter to measure the mass fuel consumption of test engines.

Standard Features

- Coriolis Mass Fuel Meter

- Measure fuel flow rates 0.5 to 125kg/hr

- Pressurized fuel delivery to the engine

- Cooling loop cools returning fuel to be cooled before being recirulated

- Constant loop pressure

- Vapor seperation system

The system connects to the fuel tank for supply and return of excess fuel. An outlet boost pump provides pressurized fuel going to the engine. A cooling loop allows fuel returning from the engine to be cooled by chilled water before recirculating back to the engine. A bubble separator collects the vapor from the engine return. A manual valve allows the operator to bleed the system back to the fuel tank.

An inlet DC-pump pulls fuel from the fuel tank. In cases where there is an in-tank pump, a bypass to the pump assures blockage-free fuel devivery. A spin-on filter reduces particles in the fuel. The relief regulator maintains the inlet pressure to the flow meter. A pressure gauge displays the current settign. The Coriolis mass flow meter measures the flow rate which is supplied to the engine loop. A regulator maintains the loop pressure, which is identical to the engine return pressure. The engine supply loop consists of a vapor seperator, a DC outlet pump, the engine fuel rail and the return heat exchanger. Parallel to the fuel rail is a relief regulator which acts as a safety relief fo the DC pump in case of dead heading or as a supply pressure regulatorin case of returnless engines. In these cases, the engine return line must be plugged. The vapor seperator collects vapor coming back from the engine. A sight guage visualizes the pressence of vapor, so the operator can open a bleed valve and return the vapor back to the fuel tank.

Transmission Control Module

The MAE-TCM allows you to wirelessly control all of the world’s largest OEM transmissions.

Standard Features

- Wirelessly control any OEM transmission

- Paddle shifting & button shifting simulation

- Controlled by wireless PDA or laptop PC

- 10 bit resolution

- Frequency range of 15hz to 50.5 Khz

- Current, resistance, and voltage tests

- 12 solenoid channels

- Easy to use Windows software interface

- Uses your existing wire harnesses

The MAE-TCM Transmission Control Module, which connects to the transmission and is secured under the hood of your vehicle, is operated from the driver’s seat using a laptop PC or handheld PDA for wireless or USB control of transmission shifting.

The MAE-TCM Transmission Control Module is a wireless transmission shifter that allows you to program and store control setups for every type of electronic automatic transmission including Ford, Nissan, GM, Toyota, Chrysler, and many other manufacturers. Electronic automatic transmissions have been mass produced for many years without a satisfactory aftermarket control solution. MAE’s unique approach to engineering allows our Transmission Control Module to control all types of electronic automatic transmission by the use of the proper frequency and duty cycle and is fully programmable via a user-friendly PC-based Shift Table Editor. Diagnosing transmission problems is made easy with the MAE-TCM.

Throttle Control And Pedal Actuators

Mustang offers both the Direct-Connect SERVO System and the versatile Gearhead System, in different actuator sizes to meet your applications torque requirements.

Standard Features

- Direct-connect Servo System or Gearhead System Available

- Reduced backlash and lag

- Extremely fast response times

- Quick and easy setup

- Built-in power reserve to return actuator to closed throttle position

DIRECT-CONNECT SERVO SYSTEM

Mustang’s Direct-Connect SERVO System is a high performance throttle actuator that eliminates the use of a gearhead assembly. This reduces the backlash and lag often associated with gearhead systems during high-speed movements. The Direct-Connect SERVO System offers extremely fast response times due to its high-effected torque-to-shaft inertia ratio and direct drive connection. The direct drive configuration allows for quick and easy setup and installations.

Due to low inertia and high torque, the SERVO actuator offers exceptional response time (50ms from 0 to 90°). A 2,000 ppr dual quadrature encoder is affixed to the actuator, which canresolve a complete shaft rotation to one part in 8,000 ppr. The system is usually configured so that the actuator moves through a 90° arc with an accuracy of 0.05%, consistent with most lab sensors and feedback devices used to measure throttle position.

GEARHEAD SYSTEM

The Gearhead System uses a precision gearhead to increase torque for use with in-vehicle pedal actuators. The gearhead’s backlash effect results in less than 0.015 inch of movement when connected to a 3 inch arm via a cable, increasing accuracy under any conditions. Because the gearhead creates an additional non-energized position holding force on the arm which may prevent a full return to 0% throttle during a power failure or E-Stop condition, the amplifier has a built in power reserve which will return the actuator to the closed throttle position. The Gearhead System is available with a wide variety of stands, supports, linkages and clamps to adapt the system to almost any application and make installation and transfer between vehicles quick and easy.

Transmission Fill/Purge System

Transmission fill/purge roll around standalone system with integral 60 gal tank

Standard Features

- Metered fill with 5/16″ fill tube

- High flow fill

- Secondary hose for purge function to drain transmissions

- Onboard dual filtration w/ standard canister type filters

- Low oil level switch

- High oil level switch

- Reservoir temperature sensors (2)

- Dirty indicators for filters

- Circulation pump for tank turnover

- Tank cleanouts both ends

- Standard 5″ sight glass

- Filler with stainless strainer and vented cap

Visit our announcement page about this transmission fill/purge stand-alone unit.