Transmission Dynamometers Literature – PDF files

Categories

| Universal Automotive Transmission Dynamometers (See Below) |

| HD Universal Transmission Dynamometers |

| Medium-Duty Transmission Dynamometers |

| Heavy-Duty Transmission Dynamometers |

| Extreme-Duty Transmission Dynamometer |

| Aviation/Helicopter Test Stands |

Universal Automotive Transmission Dynamometer

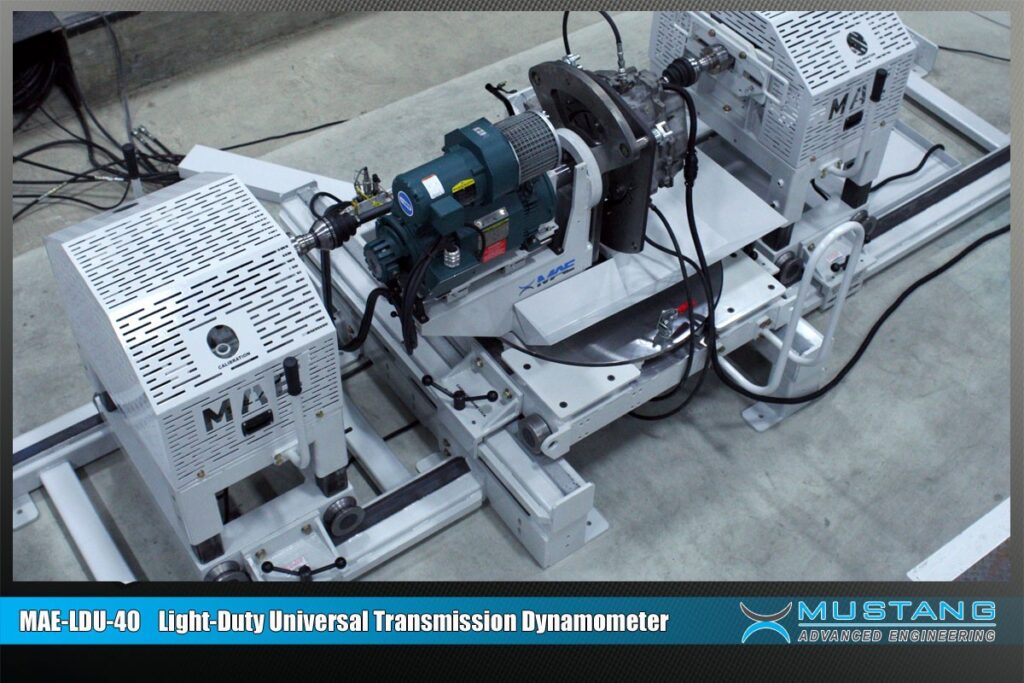

The MAE-LDU-40 Universal Automotive Transmission Dynamometer is the most advanced next-generation universal transmission dynamometer on the market.

Standard Features

- 40-hp AC Motor Engine Simulator

- 40-hp Eddy Current PAU Output Loading with torque feedback

- Includes Complete Data Acquisition System

- Upgradeable to Test With CAN communication

- MAE-TCM Electronic Shifter Included

- Script Editor & Shift Table Editor – add new transmissions with ease.

- Automated Testing and calibration programs Standard

Mustang’s latest product innovation for automotive transmission repair and remanufacturing professionals is the MAE-LDU-40, a universal automotive transmission dynamometer that represents the most advanced, next-generation dynamometer for testing automatic passenger car and light truck inline and transverse transmissions.

Mustang designed the LDU-40 to specifically address the short-comings of the standard transmission dynos found in the market today. The result is a transmission dynamometer that is more easily adaptable, more accurate, more user friendly, with a more flexible software and data acquisition package, and most importantly, is more sensible from an economic standpoint.

The LDU-40 Universal Transmission Dynamometer is a quantum leap forward from the outdated systems that once upon a time were considered state-of-the-art. Take your transmission testing to an unprecedented level of accuracy, efficiency and usability.

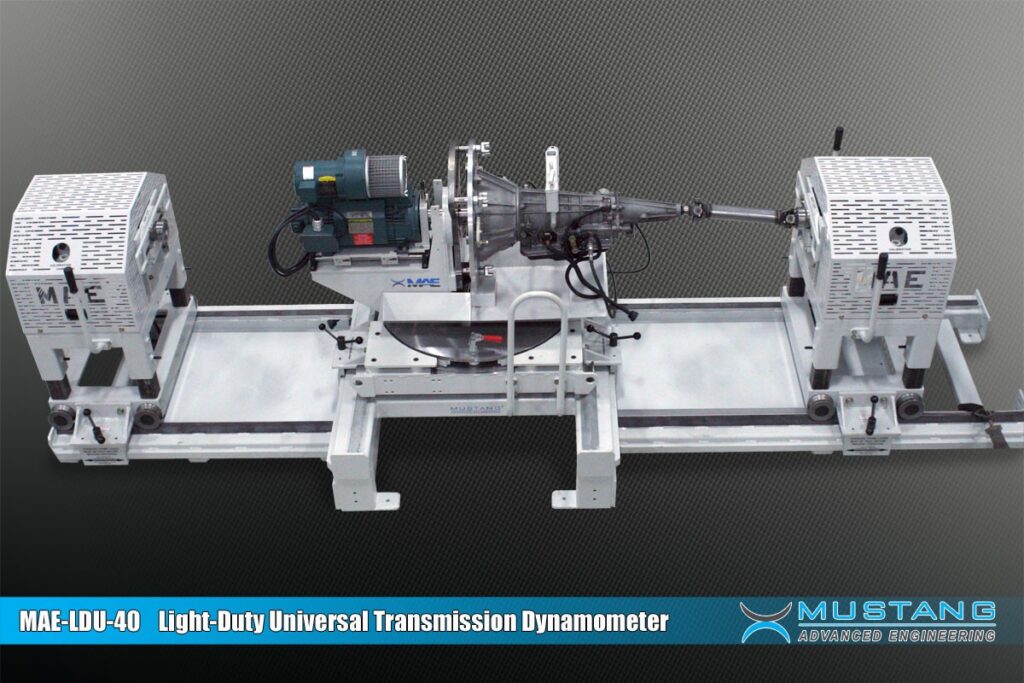

Forget the hassles of using custom mounting plates and spacers to get a torque converter fitted just right. Mount and test transmissions faster and easier than ever before with a universal system so flexible, you can change setup configurations in a matter of minutes, with a single operator.

Universal Hardware

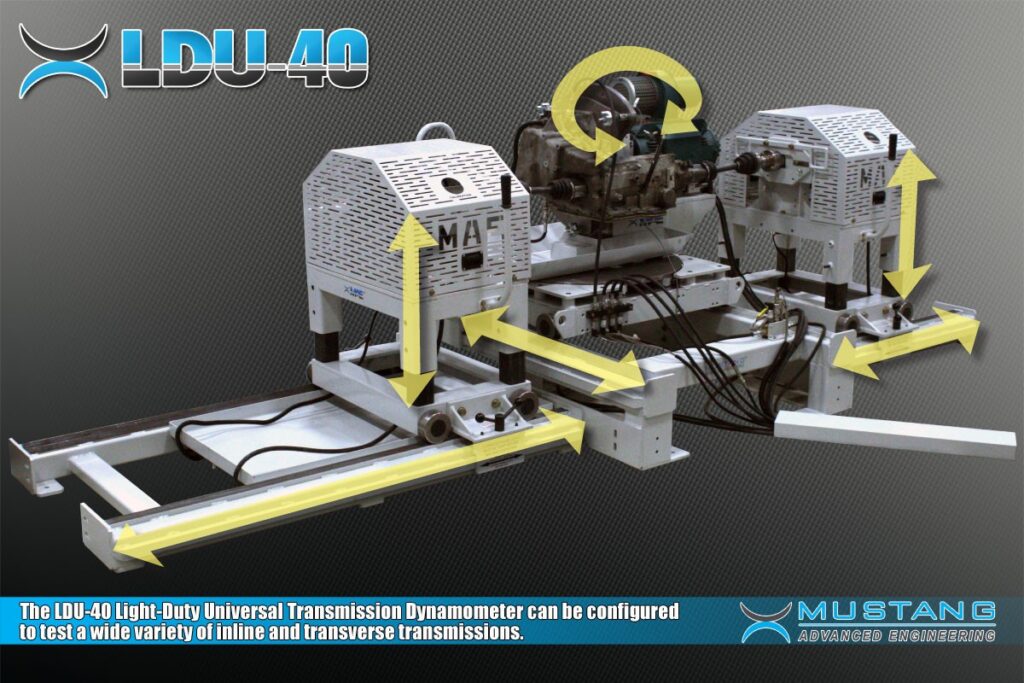

The MAE-LDU-40 transmission dynamometer is by far the most easily adaptable test system on the market. Test a wide variety domestic and foreign rear-wheel transmissions without the need to purchase countless custom mounting plates.

Our patented Universal Adapter Plate virtually eliminate the need to have expensive custom plates for each transmission you need to test – saving you both time and money and simplifying your testing operations.

Mustang’s system easily adjusts to fit any torque converter without the need for complicated spacers and bushing combinations, making it easier to center and mount more transmissions faster.

Our rotating head stock also allows you to easily adapt and configure the test stand to test front wheel drive transverse transmissions, including Honda and Mitsubishi, and longitudinal 42LE transmissions such as the Chrysler A606.

Our use of U-joint drive shafts simplifies set up and dramatically minimizes the chance of damaging rear seals due to misalignment issues.

More Accurate Test Results

The LDU-40 achieves the highest level of accuracy in the industry thanks to its high quality electronics package.

Cradle-mounted PAUs and precision strain-gauge-type load cells on each output PAU provide continuous feedback to the control loop, allowing for more precise load control and more accurate testing results.

A 30-tooth speed encoder ensures a higher resolution speed signal, and therefore a more accurate gear ratio calculation.

The LDU-40 also includes Mustang’s Transmission Control Module, The MAE-TCM, standard with every unit. The MAE-TCM gives you the ability to test a transmission using the correct frequency and duty cycle, which ensures that the transmissions are being tested exactly as they perform in a vehicle.

All this results in a more accurate dynamometer, so you can test with more confidence.

Powerful & Flexible Software

The most important feature of the LDU-40 transmission dynamometer is the power and flexibility of Mustang’s TransTester Control Software, the true heart of the system. With TransTester, you have a software package that also easily adapts to keep up with your changing needs.

Some of the significant advantages that TransTester offers include a Script Builder Utility, a Shift Table Editor, and a powerful graphing and data analysis utility. The Script Builder Utility gives you an unlimited ability to add new or modify existing scripted test procedures. With the Script Builder, you can define an unlimited number of test steps, each of which include fully customizable testing parameters. For the Input and Output parameters, you can choose between speed, torque, power or manual mode and establish mode-specific setpoints and ramp rates. The gear select control allows you to specify a gear range for this step. The step prompt allows you to enter custom text to be displayed on the test screen during this step in the test sequence. The Break on Channel Value feature can command the software to skip to a user-defined step once a user-defined condition is met. For example, once a sump temperature of 180° is reached, skip to step 6. Reported channels allows the user to define channels to record as well as minimum and maximum pass/fail criteria for each defined channel. Additional steps can be easily created by copying, pasting and editing existing steps.

TransTester’s Shift Table Editor ensures that you have the flexibility you need to set up a new transmission when the need arises. Using the Shift Table Editor, you have the ability to customize the software to shift any new transmission that may come through your door.

TransTester’s powerful graphing utility allows you to graph, analyze and export all data in an Excel-friendly format.

Key Advantages

SOFTWARE & CONTROLS

- Mustang gives you the ability to add new transmissions and shift tables using the Script Editor and Shift Table Editor in an easy to use Windows-based software environment.

- Mustang’s MAE-TCM (Electronic Shifter) give you the ability to test transmission using the correct frequency and duty cycle which ensures that transmissions are being tested exactly as they perform in a vehicle.

- Mustang’s cradle-mounted PAUs incorporate load cells which supply feedback to the control loop, allowing for precise load control and more accurate testing.

- Mustang uses a 30-tooth speed encoder which allows for a higher resolution speed signal and therefore more accurate gear ratio calculation

- Available analog outputs allow for user defined controls (ie. Control of a heat exchanger valve).

- MAE’s Script Editor includes a “Break on Value” feature that will command the software to skip to a user defined step once a user defined condition is met (ie. Temperature is achieved, then skip to step XX)

- Vehicle Simulation output mode let’s you run the transmission as though it is installed in a vehicle on the street.

- Mustang offers a utility that allows the user to calibrate pressures and load cells. This allows the customer to install and calibrate new transducers as needed.

- Mustang’s base systems include complete data acquisition and computerized system.

- Mustang systems are upgradeable to test transmissions with CAN Communication.

- Base system can read:

- Current, resistance, voltage

- 9 PWM Solenoid Outputs

- 3 Digital Solenoid Outputs

- 12 Solenoid Channels

- 8 Digital Inputs for pressure sensors, PRNDL switch, and more…

- 3 Frequency Inputs

- 2 Analog Inputs

- Control frquency from 15Hz to 50.5 KHz for testing newer solenoids that require higher frequency to properly test.

- Automated Testing Mode is standard with base system.

- Print and save data.

- Mustang is able to remotely access the customer’s Control PC via modem to troubleshoot and provide technical support.

HARDWARE

- Mustang’s system adjusts easily to fit any torque converter without any pilot bushings or spacers making it easier to mount the transmission faster.

- Mustang Patent Pending Universal Adapter System, which is part of the base system, will adapt most all transmission with one plate system.

- Requires less adapter plates which lowers cost and improves efficiency.

- 40-hp input AC motor for more testing torque.

- Capable of testing Allison Transmissions.

- Mustang’s oil reservoir is not in the frame structure of the machine but independent. This makes cleaning much easier.

- In using the eddy current as the brake there won’t be the problem with brake pad wear.

- Measuring Output Torque and providing Torque Feedback is standard.

- Mustang provides U-Joints in our adapter system. This prevents any misalignments which in turn prevents damage to rear seals on transmissions.

- Mustang’s MAE-TCM Electronic Shifter is included standard.

- Mustang supplies a Universal Cable Adapter so that you can use existing cables.

- Mustang has built in calibration program that allows recalibration of sensors such as transducers and flow meters. This allows flexibility to upgrade the system to larger transducers and flow meters with no hassle.

MAE-LDU-40 Specifications

| Trans Input AC Motor / Engine Simulator | |

| Power: | 43 Hp (30kW)- Continuous60 Hp (45kW)– Peak |

| Torque: | 90 lb-ft (120 N-m)-Continuous125 lb-ft (170 N-m) – Peak |

| Speed: | 4,000 rpm |

| Inertia: | Low inertia for proper engine simulation |

| Torque Measurement: | Electronic, Direct Torque Control |

| Torque Calibration: | NIST Load Cell Transfer |

| Type: | AC Motor, variable speed low inertia |

| Cooling: | Blower Cooled for continuous operation |

| Mounting: | Variable Linear Movement with respect to the trans mounting face plate for easy transmission mounting adjustment without shimming or spacers |

| Transmission Mounting | |

| Bell Housing Mounting: | Universal Mounting PlateIndependent Mounting PlateNo mounting plate shim spacers required |

| Tail Support: | Foot mount jack stand |

| Torque Converter Adapter: | Universal TC adapterIndependent TC flex plateTC pilot centering bushing set |

| Output Adapter: | Balanced CV and U-joint based for smooth high speed operation with transmission output adapter Hubs |

| Transmission Output Loading | |

| Type: | Air Cooled Eddy Current with electronic torque feedback |

| Output Loading: | 95-hp @ 1,800 rpm (cold), 45-hp @1,800 rpm (hot)135-hp @ 6,000 rpm (cold), 65-hp @ 6,000 rpm (hot) |

| Max Speed Deceleration/Rate: | 6,000 rpm/13,000 rpm/sec |

| Base Inertia: | 6.3 lb-ft2 (0.63 Kg-m2) |

| Vehicle Simulated Inertia Range: | 1,000-5,000 lb. vehicle (trans dependent) |

| Output Torque Response Rate: | ≤ 95 ms |

| Torque Calibration: | NIST Dead Weight |

| Mounting: | Cradle mount with electric load cell, measure both dynamic and stall torque. |

| Stall Lock: | With electronic torque feedback readings |

| Dyne & Transmission Controls | |

| Input Motor: | Engine Emulation with throttle controlEngine Torsional Vibration OverlayTorque ControlSpeed ControlManual %Kfactor |

| Output Dyne Control: | Vehicle Simulation Control with/without Inertia SimulationIndependent L/R/3O* Speed Control, Torque Control, Manual %Stall |

| Trans Control: | Manual lever shift (hydraulic)Direct Solenoid Electronic Shift (External ECM)CAN Communications Shift (internal ECM)Modulator +/- (Optional)Vacuum Simulation (Optional)Fluid Cooler (Optional) |

| System Data Acquisition: | Pressure #1 :Mainline or otherPressure #2 :Coolant or otherPressure #3 :Clutch 1 or otherPressure #4 :Clutch 2 or otherPressure #5 :Clutch 3 or otherPressure #6 :Clutch 4 or otherPressure #7 :Clutch 5 or otherFlow: CoolantTemp: FluidInput Speed (rpm) measuredInput Torque (lb-ft) measuredInput Power (Hp) CalculatedOutput L Speed (rpm) measuredOutput L Torque (lb-ft) measuredOutput L Power (Hp) calculatedOutput R Speed (rpm) measuredOutput R Torque (lb-ft) measuredOutput R Power (Hp) calculated |

| Power Requirements: | 460 VAC, 3 Phase, 80 Amp, 60 Hz – Motor230 VAC, 3 Phase, 80 Amp, 60 Hz – Dyne Control |

| Machine Dimensions: | 9.5″ × 175″ × 96.5″ (241 × 437 × 246 cm) (includes crane) |

| Machine Shipping Weight: | 4,500 lbs. (204 Kg) |

MAE’s Transmission Dynamometers are designed to test applications ranging from passenger vehicles, light and medium trucks, marine, industrial vehicles, tow motors and forklifts, ATV, agricultural vehicles and racing. The MD Series incorporates the latest motor/drive technologies to provide the ultimate AC motor control performance for input speed and torque control, while output loading is handled utilizing Eddy Current PAUs. As always, additional options are available to meet any specific performance criteria.