Our Engine Dynamometers are available in these types: AC Dynamometers, High Speed Test Stands, DGEC Series Water-cooled Eddy Current Dynamometers, ED Eddy Current Series Dynamometers, and Custom built to any specification requirements.

Engine Dynamometer Literature – PDF files

AC Dynamometers

Mustang’s AC Engine Dynamometers utilize a specialized low-inertia, high-performance AC motor and a regenerative motor drive to provide superior response, load control and accuracy, load stability, transient features and zero to full speed range capabilities.

Standard Features

- Highly Accurate, Ultra-Fast Response

- High torque – Low Inertia – High Speed

- Bi-Directional

- Low Maintenance

- Provides continuous constant torque down to zero speed

- Fractional to 1,000-hp

- Compact and lightweight design.

- 150% overload torque from zero speed to base speed

Specifications

| Model | Base Speed (RPM) | Max Speed (RPM) | Torque Nm (lb.ft.) | Power kW (Bhp) |

| AC-100-150 | 3500 | 8000 | 203 (150) | 75 (100) |

| AC-100-95 | 5500 | 8000 | 129 (95) | 75 (100) |

| AC-150-343 | 2300 | 8000 | 465 (343) | 112 (150) |

| AC-200-233 | 4500 | 8000 | 316 (233) | 149 (200) |

| AC-250-263 | 5000 | 6000 | 357 (263) | 186 (250) |

| AC-300-808 | 1950 | 5800 | 1096 (808) | 224 (300) |

| AC-300-375 | 4200 | 6800 | 508 (375) | 224 (300) |

| AC-350-735 | 2500 | 5800 | 997 (735) | 261 (350) |

| AC-400-764 | 2750 | 5800 | 1036 (764) | 298 (400) |

| AC-500-618 | 4250 | 5800 | 838 (618) | 373 (500) |

| AC-500-1811 | 1450 | 4400 | 2455 (1811) | 373 (500) |

| AC-750-2158 | 1825 | 3600 | 2926 (2158) | 559 (750) |

| AC-1000-3001 | 1750 | 3000 | 4069 (3001) | 746 (1000) |

Mustang’s AC Engine Dynamometers utilize a specialized low-inertia, high-performance AC motor and a regenerative motor drive to provide superior response, load control and accuracy, load stability, transient features and zero to full speed range capabilities. Through regeneration, the majority of the power absorbed by the AC dynamometer is returned to the power grid – resulting in an extremely “green” test stand.

The AC Dynamometer is available in a number of power and speed ranges to meet most standard applications. Custom AC Motor Dynes are available for those specialized applications that do not fit within the standard specifications.

MAE has over 35 years of experience in all phases of automotive engine and powertrain test stand development. Our experience includes supplying the drives that interface with a standard, packaged controller to the development of complete, customized systems including drives, operator control interfaces, sequencing functions, report generation, graphics and test cycle generation.

Options and Accessories:

- Advanced Data Acquisition Packages

- Data Acquisition Modules

- Engine Docking Carts

- Throttle Actuators

- Fuel Delivery, Measurement & Conditioning Modules

- Engine Coolant Heat Exchanger Module

- Charge Air Inter cooler Modules

- Financing Options Available

High Speed Test Stands (Engine Dynos)

Our experienced staff engineers are able to assist you in sizing and designing high speed test stands and support components.

Standard Features

- Up to 30,000 RPM

- Liquid Cooled

- Highly reliable

- Extremely stable

- High level of flexibility in test stand configurations

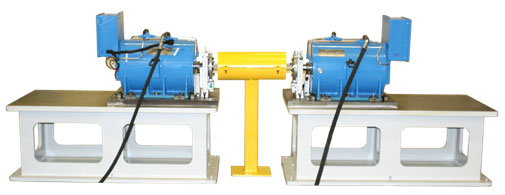

- Tandem and bi-directional configurations available

Mustang Advanced Engineering is your partner when it comes to high speed testing applications. Our experienced staff engineers are able to assist you in sizing and designing high speed test stands and support components. Typical High Speed applications include turbines, compressors, motors, engines, gearboxes, transmissions, alternators, generators and other applications requiring speeds in the range of 10,000 to 100,000 rpm. We supply both drive/loading and loading devices for these applications with the associated mounting, alignment and support equipment.

Specifications

Below is a sample of some of the high-speed motors Mustang has supplied as per specification. We have motor systems capable of direct drive speeds past up to 50,000rpm and gear driven up to 100,000rpm

AC-Loading Unit: High Speed Sample of AC-Loading Unit Offering

| Power | Power | Base Speed | Top Speed | Base Speed Torque | Base Speed Torque | Top Speed Torque | Top Speed Torque | OL (Base/Top) | Inertia | |

| Model Number | (Hp) | (kW) | (rpm) | (rpm) | (lb.-ft) | (N-m) | (lb.-ft) | (N-m) | % | Lb.-ft2 |

| MDEH-AC-25 | 25 | 19 | 20000 | 50000 | 7 | 9 | 3 | 4 | 125%/110% | <0.5 |

| MDEH-AC-47 | 47 | 35 | 9000 | 30000 | 27 | 37 | 8 | 11 | 150%/100% | <0.8 |

| MDEH-AC-100 | 100 | 75 | 10000 | 20000 | 53 | 71 | 26 | 36 | 150%/110% | 2.6 |

| MDEH-AC-200 | 200 | 149 | 7500 | 15000 | 140 | 190 | 70 | 95 | 150%/110% | 3.3 |

| 2MDEH-AC-233 | 233 | 174 | 1000 | 12000 | 1224 | 1659 | 102 | 138 | 150%/110% | 44 |

| MDEH-AC-500 | 500 | 373 | 5000 | 10000 | 525 | 712 | 263 | 356 | 150%/110% | 58 |

| MDEH-AC-800 | 800 | 597 | 7500 | 1000 | 560 | 760 | 4202 | 5697 | 150%/150% | 65 |

| MDEH-AC-1,000 | 1000 | 746 | 3000 | 6000 | 1751 | 2374 | 875 | 1187 | 120%/120% | 161 |

| 3MDEH-AC-1,300 | 1300 | 455 | 4000 | 7000 | 1707 | 2314 | 975 | 1322 | 110%/110% | 3650 |

| MDEH-AC-1,475 | 1475 | 1100 | 6000 | 7000 | 1291 | 1750 | 1107 | 1500 | 110%/110% | 69.5 |

| MDEH-AC-1,500 | 1500 | 1119 | 2100 | 6000 | 3751 | 5086 | 1313 | 1780 | 110%/110% | 465 |

2This motor is available for duel motor back to back applications for loads up to 467Hp it does have tapering power from 8,000rpm to 12,000rpm 233HP to 150Hp

3This motor has tapering power from 2,300 to 4,000rpm,1,300Hp to 750Hp, and wound at 2,300Volt

| Motor Type: | AC |

| Cooling Type: | Liquid cooled |

| Power @ 7,500 rpm: | 200 HP |

| Base Speed: | 7,450 rpm |

| Top Speed: | 15,000 rpm |

| Torque (0 to 7,450 rpm): | 176 lb-ft (238.6 N-m) |

| Torque @ 30,000 rpm: | 70 lb-ft (94.9 N-m) @ 15,000 rpm |

| Bearing lubrication: | Air-oil injection |

| Enclosure: | Liquid-gap cooled |

| Cooling Media: | ATF (automatic transmission fluid) |

DGEC Series Water-cooled Eddy Current Dynamometers

MAE’s DGECG Series Engine Dynamometers are low inertia, water-cooled eddy current dynamometers designed to provide precise and repeatable load control. DGEC Series Dynamometers are ideal for applications requiring high speed testing in the middle to high power ranges.

Standard Features

- Torque measurement accuracy ±0.25% of full rated torque

- Speed measurement accuracy ±1 RPM

- Low inertia

- Bi-directional

- High repeatability

- Low maintenance

Mustang’s DGEC Series Engine Dynamometers are low inertia, water-cooled eddy current dynamometers designed to provide precise and repeatable load control. The DGEC Series are ideal for applications requiring high speed testing in the middle to high power ranges.

Eddy-current dynamometers provide increasing torque as the speed increases, reaching peak torque at rated speed. MAE’s standard DGEC Series Dynamometers range from 25 kW to 1300 kW at speeds up to 10,000 rpm and can absorb power in either direction of rotation.

DGEC Series Dynamometers have low inertia as a result of small rotor diameter. Brake cooling is provided by a water circulation system, which passes inside the stator to dissipate heat generated by the braking power. The water cooling in the DGEC Series provides for high continuous power ratings.

DGEC Series Dynamometers include a strain gauge load cell to provide torque measurement accuracy ratings of ± 0.25% of full rated torque. Speed is measured by a pulse pickup operating with a 60 tooth wheel to provide speed measurement accuracy of ±1 rpm.

The DGEC Series Eddy Current Dynamometers are built to withstand the most demanding applications. The rugged and simple design of the WG Series ensures a long, hassle-free operating life.

MAE’s DGEC Series Engine Dynamometers provide a range of eddy current loading devices designed for testing engines from 33.5-hp to 1,744-hp (25 to 1300 kW) capacity. The strain gauge load cell provides high accuracy torque measurement for exacting test and development applications. The rugged design of the power absorbing system ensures a long operating life, even in the most demanding production and endurance testing environments. This long life is further enhanced by the electroless nickel plating of critical components that are in contact with the cooling water.

Standard Features:

- Low-inertia rotor design

- High accuracy strain gauge load cell for precise torque measurement.

- Precision control, even at low loads and rapid changes in demands.

- Bi-directional operation.

- Twin silicon rubber encapsulated energizing coils, with central ventilation to ensure reliability in extreme conditions.

- Carcase mounted in deep groove ball bearings.

- Electroless nickel plating of cooling passages to ensure corrosion-free operation.

- O-ring pipe connections to minimize torque calibration errors from vibrations in water supply pressure.

- Water flow failure warning fitted as standard.

- Precision-balanced, torsionally compliant drive shafts

- Precision bearings to ensure smooth operation.

Construction

MAE’s DGEC Series dynamometers feature fully encapsulated two piece coils, used in place of the more common and cheaper single coil arrangement. This configuration ensures optimum distribution of flux throughout the working area for maximum low speed torque, and at the same time allows the free flow of air from the center of the machine through the critical air gap between rotor and stator and then out of radial ventilation slots. These features ensure both rapid response and reliability under the most severe loading conditions – which can often be the cause of local overheating in single coil machines.

Trunion Bearings

Deep groove ball bearings provide the most precise method of carcase mounting and are virtually friction-free. They are also extremely rigid and free from resonance problems which can occur on other flexible type of mounting systems. The bearing selection also helps ensure extended service life.

Shaft and Rotor

The rotor is manufactured from high-magnetic permeability material for maximum performance and is designed for minimum inertia. Precision-grade bearings are used to ensure accurate shaft location and safe high speed operations.

The cooling passages and “loss plate” are critical areas in an eddy current dynamometer, as thermal loading is high and cyclic loading can cause corresponding temperature changes. Associated loss plate distortion may cause catastrophic contact between plate and rotor or loss of coolant. Extensive design and development has been performed on our system of loss plate mounting, which allows controlled radial expansion without water leakage and prevents loss plate distortion. The water passages have been optimized to ensure consistent cooling and are electroless nickel plated to ensure that corrosion does not detract from performance.

Water Connections

Water connection is by means of O-ring sealed articulated pipes, leading to flanges suitable for connection to the customers water supply. These ensure that water connection and supply pressure variations have minimal effect on machine accuracy. An integral flow detector monitors flow rate and ensures that a warning signal is given if water flow should drop below safe levels.

Control

The level of power absorbed is controlled by varying the excitation current at the coil. When used in conjunction with feedback signals for torque from the load cell and speed from pulse pick up and toothed wheel, closed loop control is provided. We offer both manual or automated control systems, data acquisition and alarm annunciation.

Specificiations

| Model Number | Max Speed (RPM) | Power BHP(kW) | Torque lb.ft (Nm) | PAU Style | Mounting Configuration |

| DGEC-25 | 10,000 | 33.5 (25) | 74 (100) | Drum | Pedesatal Mount |

| DGEC-50 | 10,000 | 67 (50) | 130 (176) | Drum | Pedesatal Mount |

| DGEC-100 | 10,000 | 134 (100) | 235 (318) | Drum | Pedesatal Mount |

| DGEC-150 | 6,500 | 201 (150) | 707 (955) | Drum | Pedesatal Mount |

| DGEC-160 | 10,000 | 215 (160) | 386 (522) | Drum | Pedesatal Mount |

| DGEC-260 | 7,500 | 349 (260) | 1032 (1395) | Drum | Pedesatal Mount |

| DGEC-440 | 6,500 | 590 (440) | 2045 (2764) | Drum | Pedesatal Mount |

| DGEC-550 | 3,000 | 738 (550) | 2590 (3500) | Disk | Pedesatal Mount |

| DGEC-650 | 3,000 | 872 (650) | 3062 (4138) | Disk | Pedesatal Mount |

| DGEC-850 | 3,000 | 1,140 (850) | 3996 (5400) | Disk | Pedesatal Mount |

| DGEC-1300 | 2,000 | 1,744 (1300) | 6120 (8270) | Disk | Pedesatal Mount |

Options & Accessories

- Calibration Kits (81 or imperial)

- Torsional vibration dampening drive shafts and shaft guards

- Data Acquisition systems

- Engine start systems (DC, AC, or Pneumatic)

- High-speed version

ED Eddy Current Series Dynamometers

Mustang’s ED Series Eddy Current Air-Cooled Engine Dynamometers are the answer for most engine testing applications due to their excellent stability, accuracy and testing range. Unlike similarly priced water brake systems, the ED Series offers reliable, steady state control from near zero speed to maximum RPM.

Standard Features

- Fast Response Time

- Accurate Load & Inertia Simulation

- Maintenance Free – No Water

- Four Ranges to meet most applications

- 40 Range – High speed small displacement engines

- 70 Range – 4 or 6-cylinder automotive engines

- 140 Range – 6 or 8-cylinder automotive applications and light-duty diesel engines

- 400 Range – Large heavy-duty diesel engines.

ED Series Engine Dynamometers

Mustang’s ED Series Eddy Current Engine Dynamometers are available in four ranges – the 40 Range for high speed small displacement engine testing (internal combustion engines), the 70 Range for standard automotive engines and high speed four and six cylinder racing engines, the 140 Range for standard 6-cylinder and 8-cylinder automotive applications and light and medium duty diesel engines, and the 400 Range for testing large diesel engines. The 70 and 140 Ranges each have three separate products to handle a wide range of power requirements. The 40 Range is available with two products and the 400 Range is available with three. Additionally, each system is available with optional mechanical equipment upgrades to augment the testing needs for each client – including electric starter systems, electric motors for measuring engine parasitic losses, and gear reducers for testing very high RPM engines common in motorcycles, ATVs, and snowmobiles.

The ED Series Engine Dynamometers are available in four ranges – the 40 Range for high speed small displacement engine testing (internal combustion engines), the 70 Range for standard automotive engines and high speed four and six cylinder racing engines, the 140 Range for standard 6-cylinder and 8-cylinder automotive applications and light and medium duty diesel engines, and the 400 Range for testing large diesel engines. The 70 and 140 Ranges each have three separate products to handle a wide range of power requirements. The 40 Range is available with two products and the 400 Range is available with three. Additionally, each system is available with optional mechanical equipment upgrades to augment the testing needs for each client – including electric starter systems, electric motors for measuring engine parasitic losses, and gear reducers for testing very high RPM engines common in motorcycles, ATVs, and snowmobiles.

Fast, Accurate, and Maintenance Free

The air-cooled eddy current dynamometer delivers an exceptional response time compared to alternative types of dynamometers. For instance, the ED40-10 has a response time of approximately 150 ms. Compared to an equally sized AC Dynamometer with a 100 ms response time at over twice the price, the ED40-10 is an excellent choice. Compared to the water cooled Eddy Current with < 500 ms response time and the water brake with < 1 second response time, the Air Cooled Eddy Current is by far the best choice.

The Electromagnetic Absorption Module

The ED Series Engine Dynamometers utilize Electromagnetic Absorption Modules (i.e. Eddy Current Brakes) to apply a load to the engine under test. The Eddy Current Brake is ideal for engine testing due to its frictionless operation and relatively easy to maintain design. Each absorber is equipped with a series of coils, which, when energized with power from the system controller, will create a magnetic attraction between the stator assembly and the rotor assemblies which are connected to the test system shaft. This creates a braking, or loading action against the engine. A load cell measures the reaction torque while a highly accurate hall-effect speed sensor measures shaft speed.

Another excellent attribute of the Eddy Current Brake is the absence of water as a cooling medium. The Eddy Current Brake is air-cooled and uses specially design rotor fins to aid in the cooling process as the brake rotors spins at high speeds. Each system is also available with optional cooling fans to keep the system at a lower temperature during long term testing procedures, such as with durability testing.

Specifications

| Model # | Brake HP | Brake Torque (lb-ft) | Max Speed (RPM) | Moment of Inertia (lb-ft²) | Hot Capacity* (%) | Continuous Capacity² (%) |

| ED40-10 | 130 | 284 | 10,000 | 7 | 50 | 30 |

| ED40-20 | 260 | 568 | 10,000 | 14.5 | 50 | 30 |

| ED70-10 | 250 | 570 | 9,500 | 14 | 50 | 30 |

| ED70-20 | 500 | 1,140 | 9,500 | 29 | 50 | 30 |

| ED70-30 | 750 | 1,710 | 9,500 | 44 | 50 | 30 |

| ED140-10 | 750 | 1,700 | 6,000 | 41 | 50 | 30 |

| ED140-20 | 1,500 | 3,400 | 6,000 | 83 | 50 | 30 |

| ED140-30 | 2,250 | 5,100 | 6,000 | 123 | 50 | 30 |

| ED400-10 | 850 | 2,100 | 6,700 | 115 | 50 | 30 |

| ED400-20 | 1,750 | 4,200 | 6,700 | 240 | 50 | 30 |

| ED400-30 | 2,550 | 6,300 | 6,700 | 360 | 50 | 30 |

| ED400-40 | 3,400 | 8,400 | 6,700 | 500 | 50 | 30 |

Options & Accessories

- Advanced Data Acquisition Packages

- Data Acquisition Modules

- Engine Docking Carts

- Throttle Actuators

- Electric Starter Systems

- Fuel Delivery, Measurement & Conditioning Modules

- Engine Coolant Heat Exchanger Module

- Charge Air Inter cooler Modules

- Financing Options Available

Electric Motor Testing

If you require Electric motor Mustang has the experience and capabilities to supply you with a test stand capable of meeting your requirements. We have loading units capable of 100,000rpm and power up to 15Mega Watts. We can supply all components for your electric motor testing requirements:

| AC/DC/Hybrid Electric Motor Controllers | Electric Wave Form Monitors and Analyzers | Power Analyzers | Thermo Climatic Chambers |

| Data Acquisition Systems | Wireless / Telemetry | Liquid Cooling Systems | Battery Simulators |

| Battery Management Systems | Battery Testing Systems | Stands, Fixtures and Adapters | Loading Units with torque and speed measurement |

MAE supplies a broad range of electric motor testing equipment that covers many different motor load and speed ranges:

Small sized motors used for fan and actuator controls: fractional to 50Hp (fractional to 37kW)

Medium sized used for vehicle propulsion: 25 to 1,500Hp (18.7kW to 1,120kW)

Large size used for Wind Turbine, ship propulsion, drilling: (500 to 20,000Hp (375kW to 15,000kW)

Each different motor type requires different facility support items to operate the motor and motor drive correctly as well as monitor the motor sensor information. Each motor type and its associated testing specifications will determine which type of loading unit(s) will be attached to absorb the motors output power. The load unit will also require facility support equipment to properly operate. The load and speed control of the test motor and load unit will require an interface to the operator which will be accomplished through a test cell control system with operator software system. Depending on the test cell requirements the test cell control system can also be interfaced to the test motor support items, load unit support items, facility support items and the facility safety and fire system. In most cases the test motor will require a data acquisition system comprised of sensors which are attached to the test article to monitor the health of the test motor while under test.

During the design of the motor testing system Mustang and our customer will performs a full analyze of the motor testing specifications and the test motor’s facilities equipment interface needs. Sometimes different testing specifications requires a loading unit to both load and motor, such as to perform regenerative loading on the motor, ie making it a generator, or verifying parasitic losses. Once we define the loading/motoring testing needs we then define the specifications for the motor loading unit and it supporting subsystems. Mustang supports various motor loading unit types;

typical motor loading units are:

- AC-Loading Units

- Eddy Current Loading Units

- Water Brake Loading Units

- Sometimes these loading units may be combined with a gearbox depending on motor performance criteria and physical attachment capabilities.

- Other type of loading units can be supplied as required by the application.

- Reference the Specification Tab for more information on loading units and other facility and test cell components

After we determine the proper loading unit type(s) we look at the facility infrastructure requirement to support the test motor, the loading unit and any other required test cell subsystems. Mustang can design, size, supply and or install all facility infrastructure sub-systems to support the complete test facility this can be performed for a single test cell or a complete facility with multiple test cells.

Motoring/Loading Units:

Standard – AC-Loading (Unit Low Speed High Torque)

| AC-Loading Unit: Low Speed High Torque | ||||||||||

| Model Number | Power | Speed Range(Base Spd/Top Spd) | Base Spd Torque | Top Spd Torque | OL(Base/Top) | Inertia | ||||

| (Hp) | (kW) | (rpm) | (rpm) | (lb.-ft) | (N-m) | (lb.-ft) | (N-m) | % | Lb.-ft2 | |

| AC – Low Speed/High Torque | ||||||||||

| MDE-AC-50 | 50 | 37 | 4300 | 12000 | 61 | 83 | 22 | 30 | 150%/135% | 0.8 |

| MDE-AC-130 | 130 | 97 | 1750 | 8000 | 390 | 529 | 85 | 116 | 150%/150% | 4.9 |

| MDE-AC-210 | 210 | 157 | 1750 | 6800 | 630 | 854 | 162 | 220 | 150%/150% | 11.1 |

| MDE-AC-325 | 325 | 242 | 1750 | 5800 | 975 | 1322 | 294 | 399 | 150%/150% | 24 |

| MDE-AC-455 | 465 | 347 | 1750 | 5000 | 1396 | 1892 | 488 | 662 | 150%/150% | 45 |

| MDE-AC-620 | 620 | 463 | 1750 | 4400 | 1861 | 2523 | 740 | 1003 | 150%/150% | 85 |

| MDE-AC-875 | 875 | 653 | 1750 | 3800 | 2626 | 3560 | 1209 | 1640 | 150%/150% | 207 |

| MDE-AC-1000 | 1000 | 746 | 1750 | 3650 | 3001 | 4069 | 1439 | 1951 | 150%/110% | 230 |

| MDE-AC-1,645* | 1645 | 1227 | 2000 | 3200 | 4320 | 5857 | 2700 | 3660 | 110%/110% | 610 |

| MDE-AC-2,140 | 2140 | 1596 | 2000 | 2700 | 5620 | 7619 | 4163 | 5644 | 110%/110% | 794 |

| Powers up to 15MW are available please contact Mustang for sizing these larger units |

*Top Speed can Achieve 3,600rpm with derating

Below is a sample of some of the high-speed motors Mustang has supplied as per specification. We have motor systems capable of direct drive speeds past up to 50,000rpm and gear driven up to 100,000rpm

| AC-Loading Unit: High Speed Sample of AC-Loading Unit Offering | ||||||||||

| Model Number | Power | Speed Range(Base Spd/Top Spd) | Base Spd Torque | Top Spd Torque | OL(Base/Top) | Inertia | ||||

| (Hp) | (kW) | (rpm) | (rpm) | (lb.-ft) | (N-m) | (lb.-ft) | (N-m) | % | Lb.-ft2 | |

| AC – High Speed Sample | ||||||||||

| MDEH-AC-25 | 25 | 19 | 20000 | 50000 | 7 | 9 | 3 | 4 | 125%/110% | <0.5 |

| MDEH-AC-47 | 47 | 35 | 9000 | 30000 | 27 | 37 | 8 | 11 | 150%/100% | <0.8 |

| MDEH-AC-100 | 100 | 75 | 10000 | 20000 | 53 | 71 | 26 | 36 | 150%/110% | 2.6 |

| MDEH-AC-200 | 200 | 149 | 7500 | 15000 | 140 | 190 | 70 | 95 | 150%/110% | 3.3 |

| MDEH-AC-233* | 233 | 174 | 1000 | 12000 | 1224 | 1659 | 102 | 138 | 150%/110% | 44 |

| MDEH-AC-500 | 500 | 373 | 5000 | 10000 | 525 | 712 | 263 | 356 | 150%/110% | 58 |

| MDEH-AC-800 | 800 | 597 | 7500 | 10000 | 560 | 760 | 4202 | 5697 | 150%/150% | 65 |

| MDEH-AC-1,000 | 1000 | 746 | 3000 | 6000 | 1751 | 2374 | 875 | 1187 | 120%/120% | 161 |

| MDEH-AC-1,300** | 1300 | 455 | 4000 | 7000 | 1707 | 2314 | 975 | 1322 | 110%/110% | 3650 |

| MDEH-AC-1,475 | 1475 | 1100 | 6000 | 7000 | 1291 | 1750 | 1107 | 1500 | 110%/110% | 69.5 |

| MDEH-AC-1,500 | 1500 | 1119 | 2100 | 6000 | 3751 | 5086 | 1313 | 1780 | 110%/110% | 465 |

| Lower Powers and higher power up to 8MW are available please contact Mustang for sizing these units |

*This motor is available for duel motor back to back applications for loads up to 467Hp it does have tapering power from 8,000rpm to 12,000rpm 233HP to 150Hp

**This motor has tapering power from 2,300 to 4,000rpm,1,300Hp to 750Hp, and wound at 2,300Volt

Pre-Fabricated Containerized Dynos – Modular Testing Facilities

- Highly-flexible, modular designs allow multiple units to be assembled into a complete test facility on-site.

- Allows for fast and low-cost relocation of test facilities.

- Turnkey containerized test cells or complete facilities.

- Connection of service lines is only requirement once on-site.

- Self-contained systems can include air conditioning systems, exhaust extraction systems, water and coolant conditioning systems, compressed air system, fuel delivery, conditioning and measurement systems, fire extinguishing systems and separate operator control rooms and system facilities rooms.